Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

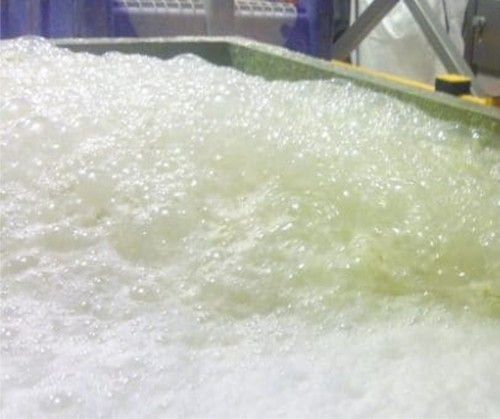

Non Silicone Defoamer

Product Details:

- Solubility Dispersible in water

- Poisonous No

- Taste Odorless

- Ph Level 6.5 - 7.5

- Storage Store in cool, dry place

- Purity 99%

- Density 1.02 Gram per cubic centimeter(g/cm3)

- Click to view more

Non Silicone Defoamer Price And Quantity

- 200.00 - 1000.00 INR/Kilograms

- 20kgs Kilograms

Non Silicone Defoamer Product Specifications

- 1.02 Gram per cubic centimeter(g/cm3)

- Not available

- Industrial

- Chemical Auxiliary Agent

- Mild characteristic

- Defoamer

- 99%

- Defoaming agent

- Liquid

- Odorless

- Industrial Grade

- No

- Industrial Standard

- Non Silicone Defoamer

- Non-silicone

- Store in cool, dry place

- 6.5 - 7.5

- Non-silicone Defoamer

- Dispersible in water

- Liquid

Non Silicone Defoamer Trade Information

- 10 Kilograms Per Day

- 2 - 3 Days

- Asia, Africa

- All India

Product Description

From our quality-assured range, we are exporting, processing and supplying a wide gamut of Non Silicone Defoamer. This deformer can easily replace silicone defoamer as it causes separation and spotting problems being 100%% active compound. In order to increase the demand of the product, we provide these deformers into various concentrations and compositions. The Non Silicone Defoaming Agent is widely applied in the Paints & Coating Industry and the Polymerisation & Distillation Industry for controlling the re-foaming tendency of surfactants that are incorporated into the system.

Additional Information: (Additive 5118)

With immense experience in the industry, we are actively engaged in offering supreme quality Silicone Defoamer that finds extensive usage in distinct industries such as printing inks, paints, adhesives, lubricating oil, etc. The defoamer offered by us is processed by making use of optimum quality chemical compounds and the latest techniques under the guidance of our skilled professionals as per the standards laid down by the industry. We offer this Silicone Defoamer in various packaging options at pocket friendly prices to our clients.

Key Features of Effluent Defoamer

- Boasts a prolonged shelf life, ensuring sustained effectiveness and consistent defoaming performance

- Crafted with environmentally responsible materials

- Formulated with precision

- Poses no harm to health or the environment, being non-toxic

- Technical Data of Non Silicone Defoamer :

| Appearance | Pale Straw Hazy Free Flowing Liquid |

| Type of Surfactant | Non-ionic |

| Active Content | 30%% |

| Flash Point | 65 DegC |

| Solvent | Aromatic Hydrocarbon |

| Miscibility | Miscible with Aliphatic and Aromatic Hydrocarbon |

| Sp. Gravity | 0.88 |

| HAP | <0.01%% |

Dose Level:

0.05 to 0.2%% is enough to antifoam and control re-generation of foaming.

FAQs of Non Silicone Defoamer:

Q: How should Non Silicone Defoamer be used in industrial applications?

A: Non Silicone Defoamer should be added directly to process liquids at a recommended dosage of 0.010.3%% by weight, or as required. It disperses easily in water and can be mixed during processing to control foam formation effectively.Q: What are the main benefits of using a non-silicone defoamer?

A: The primary benefits include compatibility with sensitive systems, no silicone contamination, excellent dispersion in water-based solutions, odorless handling, and non-poisonous composition, ensuring user safety and product integrity.Q: When is it optimal to apply Non Silicone Defoamer during a process?

A: It is best to introduce the defoamer at the initial stages of your process or whenever foam formation becomes noticeable, enabling timely foam management and maintaining operational efficiency.Q: Where should Non Silicone Defoamer be stored?

A: Store the product in a cool, dry place away from direct sunlight or high humidity. Proper storage ensures the defoamer retains its properties for up to 12 months.Q: What makes this defoamer suitable for a wide range of industrial liquids?

A: Its non-ionic nature and excellent compatibility with most process liquids make it versatile. It is highly dispersible and maintains stability up to 80C, allowing use with many industrial systems.Q: Is Non Silicone Defoamer safe to use and handle?

A: Yes, it is non-poisonous, odorless, and conforms to industrial safety standards. It can be handled with standard chemical safety precautions.Q: Does the defoamer have any smell or taste that affects production processes?

A: The product has a mild characteristic smell and is odorless in practical use. It does not alter the taste or aroma of process liquids, making it suitable for sensitive industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Antifoaming Agent' category

|

HARMONY ADDITIVES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |