Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

HARMONY ADDITIVES PRIVATE LIMITED

Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

Polyglycol Defoamer

200.00 - 1000.00 INR/Kilograms

Product Details:

- Ph Level 7.0 1

- Storage Room Temperature

- Purity 100%

- Form Liquid

- Solubility Cool Water

- Chemical Name Defoamer

- Grade Industrial Grade

- Click to view more

X

Polyglycol Defoamer Price And Quantity

- 200.00 - 1000.00 INR/Kilograms

- 20kgs Kilograms

Polyglycol Defoamer Product Specifications

- Industrial, Paints

- Room Temperature

- 100%

- Cool Water

- 7.0 1

- Defoamer

- Industrial Grade

- Liquid

Polyglycol Defoamer Trade Information

- 10 Kilograms Per Day

- 2 - 3 Days

- All India

Product Description

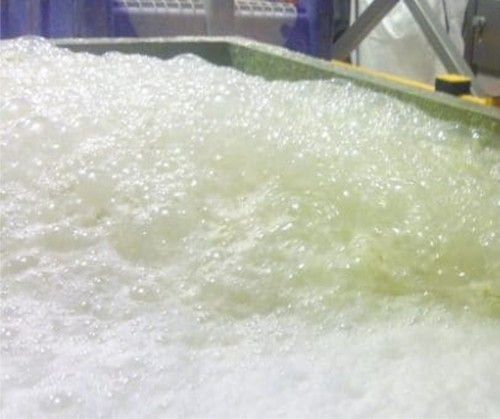

We are known as one of the foremost manufacturer, engaged in exporting the best quality stock of Polyglycol Defoamer. The defoamer is an excellent quality emulsion of activated silicone oil with a perfect blend of proprietary surfactants in mineral oil. It is used not only used for bursting the foams but also for controlling its re-generation. This Polyglycol Defoamer is extensively used in a variety of printing inks, paints, adhesives, pulp & paper processing, paper coating aqueous pesticides and fertilizers.

Key points of Polyglycol Defoamer: Our Polyglycol Defoamer is engineered to have an extended shelf life, Formulated for superior stability, The defoamer offers a long shelf life

Specifications of Polyglycol Defoamer:

- Appearance Viscous Emulsion

- Colour Milky White

- Type of Emulsion Non-ionic

- pH of 2% Solution 7.0 1

- Flash Point Greater Than 315 Degree C

- Diluent Cool Water

Applications of Polyglycol Defoamer:

- Printing Inks, Paints

- Latex Emulsions

- Latex Binders for Carpets

- Adhesives

- Pulp & Paper Processing

- Paper Coating Operations

- Lubricating Oil Industry

- Textile Finishes

- Water Treatment

- Effluent Treatment Plants

- Vat Dyes

- Aqueous Pesticides

- Aqueous Fertilizers

- Natural Gums and their Derivatives

- Metal Industry

Incorporation Method :

- Aqueous Paints, Inks & Paper Coating: Addition at Grind Stage and Let Down stage under agitation. All other industries at any stage in after diluting with Water

Dose Level:

- Being very effective just 0.200 to 0.500% is sufficient to Defoam and control re-generation of Foam. However, final dose level will vary depending upon foaming tendency of the system, type & quantity of Surfactant present in the system. It is suggested to determine Final Dose by conducting Trial/s.

FAQs of Polyglycol Defoamer:

Q: What is the application of Polyglycol Defoamer?

A: Polyglycol Defoamer is designed for industrial applications, including paints.Q: What is the recommended storage condition for Polyglycol Defoamer?

A: It should be stored at room temperature.Q: What is the form of Polyglycol Defoamer, and what grade is it?

A: Polyglycol Defoamer is a liquid and comes in industrial grade.Q: Is Polyglycol Defoamer soluble in cool water?

A: Yes, Polyglycol Defoamer is soluble in cool water.Q: What is the pH level of Polyglycol Defoamer?

A: The pH level of Polyglycol Defoamer is 7.0.Q: What is the chemical purity of Polyglycol Defoamer?

A: Polyglycol Defoamer has a purity of 100%.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Antifoaming Agent' category

In particular, we offer only raw material/chemical for phenyl production.

|

HARMONY ADDITIVES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |