Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

Manufacturer & Exporter ISO 14001 : 2004 & ISO 9001 : 2008 Certified Group

10% Active Silicone Defoamer

Product Details:

- HS Code 34021300

- Form Liquid

- Density 1.02 Gram per cubic centimeter(g/cm3)

- Poisonous No

- Shape Liquid

- Taste Odorless

- Refractive Rate Not Determined

- Click to view more

10% Active Silicone Defoamer Price And Quantity

- 200.00 - 1000.00 INR/Kilograms

- 20 Kilograms

- >100C

- Non-ionic

- Non-toxic

- 2C

- 10100 ppm (Depending on process)

- Easily dispersible in water

- Non-film forming

- White to off-white

- Stable under recommended storage conditions

- 10 1%

- 12 Months

- Milky White Emulsion

- 50 kg, 200 kg HDPE drums

- <5 micron (average)

- 5001500 mPa.s (at 25C)

- Compatible with most process chemicals

- Polydimethylsiloxane

- 3 10

- Biodegradable, eco-friendly

10% Active Silicone Defoamer Product Specifications

- Liquid

- No

- 1.02 Gram per cubic centimeter(g/cm3)

- Liquid

- Industrial Standard

- 34021300

- Defoamer

- 63148-62-9

- Mixture (mainly polydimethylsiloxane)

- Chemical Auxiliary Agent

- Industrial

- Industrial Grade

- Not Determined

- Odorless

- Cool Water

- Foam Control Agent

- Silicone Compound

- 232-489-9

- Silicone Emulsion Defoamer

- Silicone Defoamer

- (CHOSi)n

- Store in cool, dry place, tightly sealed

- 6.5 8.5

- 10% Active Content

- >100C

- Characteristic

- >100C

- Non-ionic

- Non-toxic

- 2C

- 10100 ppm (Depending on process)

- Easily dispersible in water

- Non-film forming

- White to off-white

- Stable under recommended storage conditions

- 10 1%

- 12 Months

- Milky White Emulsion

- 50 kg, 200 kg HDPE drums

- <5 micron (average)

- 5001500 mPa.s (at 25C)

- Compatible with most process chemicals

- Polydimethylsiloxane

- 3 10

- Biodegradable, eco-friendly

10% Active Silicone Defoamer Trade Information

- 10 Kilograms Per Day

- 2 - 3 Days

Product Description

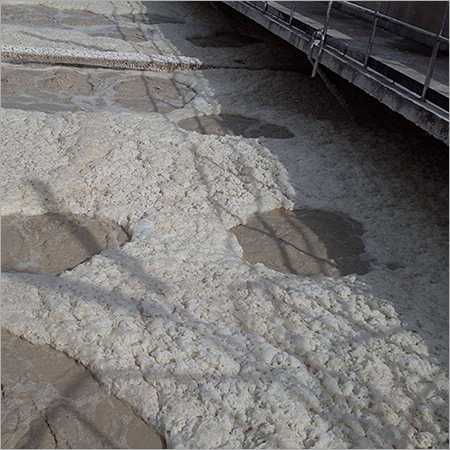

Enhance your foam control strategy with our 10%% Active Silicone Defoamer. This concentrated solution effectively eliminates foam in various industrial processes, from manufacturing to wastewater treatment. With a 10%% active silicone content, it ensures potent defoaming capabilities. Easy to apply and highly efficient, this defoamer guarantees consistent results in diverse applications. Elevate your operations with our 10%% Active Silicone Defoamer, where potency meets performance for reliable foam control in a variety of settings. Say goodbye to foam-related challenges and welcome a more streamlined, efficient workflow with this high-performance defoaming solution.

Product details

| Appearance | Viscous to Free Flowing Emulsion |

| Colour | Translucent to Milky white |

| Diluent | Cool Water |

| pH of 2%% Solution | 7 |

| Type of Emulsion | Non Iconic |

| Specific Gravity | 0.94 +/- 0.02 |

FAQs of 10%% Active Silicone Defoamer:

Q: How should the 10%% active silicone defoamer be used in industrial processes?

A: This defoamer should be added directly to the process system at a recommended dose of 10100 ppm, depending on the severity of foam. It disperses easily in water and is suitable for continuous or batch addition to suppress foam during operations.Q: What are the main benefits of using this silicone defoamer?

A: The primary benefits include rapid foam reduction, compatibility with most process chemicals, safe handling due to its non-toxic and non-poisonous characteristics, and environmental advantages from its biodegradable formulation.Q: When should I add silicone defoamer to my process?

A: Silicone defoamer should be used whenever excessive foam is detected or anticipated, typically during mixing, fermentation, chemical processing, or water treatment, to prevent operational disruptions and improve efficiency.Q: Where is this defoamer best applied?

A: It can be used across a wide range of industrial sectors, including textiles, wastewater treatment, chemical manufacturing, food processing (non-film forming grade only), and paper industries, wherever foam control is required.Q: What makes this silicone defoamer environmentally friendly?

A: The product is formulated to be fully biodegradable and eco-friendly, minimizing environmental impact during and after its application. Its non-toxic nature ensures safety for both operators and surrounding environments.Q: Is the silicone defoamer compatible with other chemicals in my process?

A: Yes, the non-ionic silicone defoamer is designed to be compatible with most process chemicals, ensuring it integrates smoothly without causing unwanted interactions.Q: How should the defoamer be stored for maximum stability?

A: Store the silicone defoamer in a cool, dry place in tightly sealed HDPE drums. Proper storage under recommended conditions ensures stability and effectiveness for up to 12 months.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Defoamers for Aqueous Systems' category

|

HARMONY ADDITIVES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |