Product Description

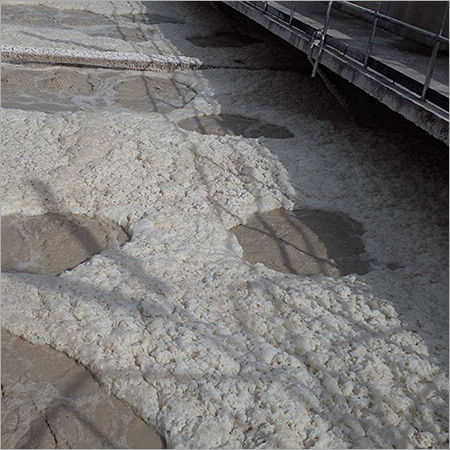

A defoamer agent, also known as an anti-foaming agent or defoamer, is a chemical additive used to control and eliminate foam in various industrial processes. Foam is the result of the accumulation of gas bubbles in a liquid, which can interfere with the efficiency and effectiveness of certain operations. In many cases, foam formation is undesirable because it can lead to several issues:

- Reduced process efficiency: Foam can hinder heat transfer, mass transfer, and fluid flow, resulting in decreased process efficiency and productivity.

- Equipment damage: Excessive foam can cause damage to equipment, such as pumps and agitators, due to increased stress and wear on components.

- Inconsistent product quality: In industries like food, beverage, and pharmaceuticals, excess foam can impact the quality of the final product.

- Safety hazards: In some cases, foam can pose safety risks, such as obstructing sightlines, interfering with sensors, or causing overflows.

Defoamer agents are designed to reduce and control foam by either destabilizing and coalescing the foam bubbles or preventing their formation altogether. These agents are generally surface-active compounds, and they work by:

- Breaking down foam bubbles: Defoamers reduce surface tension, causing the foam bubbles to collapse or merge into larger bubbles, which eventually burst.

- Coalescing foam: Defoamers can promote coalescence, where smaller foam bubbles combine to form larger ones, making them easier to remove.

- Spreading over the liquid surface: Some defoamers work by spreading over the liquid's surface, forming a thin film that prevents the formation of foam.

Defoamer agents are used in a wide range of industries, including:

- Food and beverage processing: In the production of beverages, such as beer, soft drinks, and fruit juices, to prevent excessive foam during fermentation and filling processes.

- Pulp and paper industry: To control foam in pulp washing, paper coating, and wastewater treatment.

- Oil and gas industry: To prevent foam formation during drilling, oil refining, and wastewater treatment processes.

- Water treatment: To control foam in wastewater treatment plants and water purification processes.

- Paints and coatings: To eliminate foam during the manufacturing and application of paints, varnishes, and coatings.

- Chemical processing: To control foam in various chemical reactions and production processes.

Defoamer agents come in various forms, including emulsions, powders, and silicone-based compounds, and their selection depends on the specific application and type of foam being encountered. It's essential to choose the appropriate defoamer for a particular process to ensure optimal performance and avoid any potential adverse effects on the final product or the environment.

Superior Foam Control for Industrial Processes

Our silicone-based Defoamer Agent offers efficient suppression of unwanted foam in various industrial applications, helping maintain optimal system performance. Its fast dispersibility enable rapid foam breakdown, and its stability ensures consistent results over time. The product is compatible across a broad pH range, making it suitable for diverse industrial needs.

Eco-Friendly and Safe Chemical Auxiliary

Defoamer Agent is formulated with environmentally responsible ingredients, making it both biodegradable and non-poisonous. Its mild characteristic odor and lack of taste enhance workplace safety. With high purity levels, it minimizes contamination while delivering the required antifoaming performance.

Flexible Application and Reliable Packaging

Available in multiple drum sizes (25 kg, 50 kg, 200 kg HDPE), our Defoamer Agent is tailored for convenient use in industrial environments. It is designed to be stored in cool, dry areas with tightly closed containers, which helps preserve its shelf life and stability for up to 12 months.

FAQs of Defoamer Agent:

Q: How should Defoamer Agent be used in industrial processes?

A: Defoamer Agent should be added directly to the system at a recommended dosage of 0.01%%0.5%% of the total volume, depending on foam intensity and operational requirements. It disperses rapidly and is compatible with most industrial chemicals, making it suitable for continuous or batch processing.

Q: What are the benefits of using this Defoamer Agent in manufacturing?

A: Using Defoamer Agent ensures efficient foam control, which improves process reliability and product quality. Its quick dispersibility and compatibility with wide pH ranges minimize processing interruptions, and its eco-friendly formula supports sustainability initiatives.

Q: When is the optimal time to add the Defoamer Agent during processing?

A: For best results, it is advised to add the Defoamer Agent at the initial stage or during the presence of visible foam to achieve rapid breakdown. Its stability and effectiveness persist throughout various processing conditions.

Q: Where can I apply this Defoamer Agent?

A: This defoamer is ideal for industrial applications such as water treatment, chemical manufacturing, and other processes where foam suppression is needed. It can be used in any system with aqueous components due to its high solubility and wide pH compatibility.

Q: What is the process for storing and handling Defoamer Agent?

A: Store Defoamer Agent in a cool, dry area with the container tightly sealed to ensure product stability and maintain shelf life for up to 12 months. Standard industrial safety guidelines should be followed during handling.

Q: Is Defoamer Agent environmentally safe and non-toxic?

A: Yes, the agent is biodegradable, eco-friendly, and non-poisonous, posing minimal risk to workers and the environment during use in recommended industrial applications.