Product Description

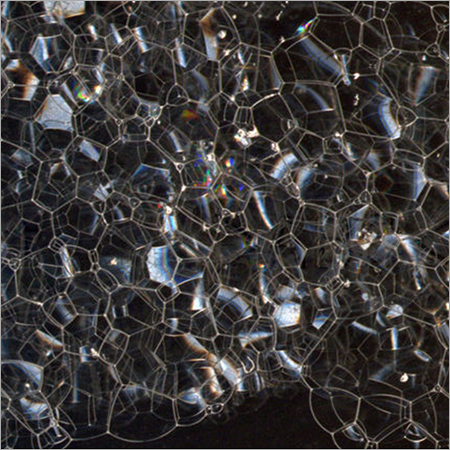

Industrial antifoam, also known as defoamer, is a type of chemical additive used to control and eliminate foam formation in industrial processes. Foam can be generated during various manufacturing and industrial operations due to the presence of surfactants, agitation, or other factors. While foam is not always undesirable, excessive foam can lead to operational issues, reduced efficiency, and potential safety hazards.

Industrial antifoam agents work by disrupting the foam structure, causing the bubbles to collapse or coalesce, which reduces the surface tension and stabilizing properties of the foam. This, in turn, helps in preventing foam formation or aiding in the rapid dissipation of existing foam.

The choice of antifoam depends on the specific industrial application, the type of foam, and the process conditions. Some common industries where antifoams are used include:

1. Food and Beverage: In the production of beverages like beer, soft drinks, and juices, antifoam agents are used to prevent excessive foaming during fermentation or carbonation processes.

2. Chemical Manufacturing: In various chemical reactions and mixing processes, foam can interfere with efficient mixing or hinder reaction rates. Antifoam is used to address these challenges.

3. Water Treatment: In wastewater treatment plants or other water treatment processes, antifoams are employed to control foam generated due to the presence of organic matter or surfactants.

4. Oil and Gas: In drilling and production operations, foam can be a problem, especially in drilling muds or during oil processing. Antifoams help to manage foam in these applications.

5. Pulp and Paper: During pulp washing and paper production, antifoams are used to control foam generated by the mechanical agitation of pulp or chemical additives.

6. Pharmaceutical: In the production of vaccines, antibiotics, and other pharmaceutical products, antifoams are utilized to prevent excessive foaming during fermentation or mixing processes.

Its essential to select the appropriate antifoam based on compatibility with the process, safety considerations, and environmental regulations. Some antifoams are silicone-based, while others may be mineral oil-based or water-based, depending on the requirements of the application.

As with any chemical additive, its crucial to handle and use industrial antifoams with care, following the manufacturers recommendations and safety guidelines to ensure safe and effective operation.

Superior Foam Control for Industry

Industrial Antifoam offers outstanding foam reduction capabilities, ensuring uninterrupted operations and optimal productivity in sectors like pharmaceuticals, chemical processing, wastewater treatment, and food manufacturing. Its advanced silicone-based formula provides reliable performance, enhancing efficiency and protecting equipment from foam-related issues. The product is safe, non-poisonous, and meets current industrial standards.

Safe, Compatible, and Easy to Use

This antifoam agent is formulated to be compatible with most process liquids. It disperses efficiently, requires no complex mixing procedures, and is insoluble yet easily dispersible in water-based systems. With non-conductive properties, neutral pH, and biodegradable material, it supports stringent environmental and safety protocols across industrial applications.

FAQs of Industrial Antifoam:

Q: How should Industrial Antifoam be applied in a manufacturing process?

A: The recommended dosage of Industrial Antifoam is typically between 10 and 100 ppm per application, depending on the level of foam present. It should be added directly to the process liquid, where it disperses quickly to suppress foam formation effectively.

Q: What benefits does this silicone-based antifoam offer over other foam control agents?

A: Industrial Antifoam rapidly reduces surface foam and is stable across a broad pH range, making it suitable for diverse industrial processes. Its technical grade purity ensures consistent results, while its biodegradability and safety profile minimize environmental impact.

Q: When is the optimal time to dose antifoam in a process stream?

A: Antifoam should be added at the onset of foam formation or integrated as a preventative measure during production cycles where foam is anticipated, optimizing foam control from the start and preventing equipment issues.

Q: Where should Industrial Antifoam be stored for best performance and shelf life?

A: Store the antifoam agent in tightly sealed HDPE drums at temperatures between 5C and 35C, away from direct sunlight and incompatible materials. Under these conditions, the product remains effective for up to 12 months.

Q: What processes and industries commonly use this defoamer?

A: This product is widely utilized in chemical manufacturing, food processing, wastewater treatment, pharmaceuticals, and other sectors where foam generation can disrupt operations or impact product quality.

Q: Is Industrial Antifoam safe and environmentally friendly for routine industrial use?

A: Yes, the antifoam is non-poisonous, biodegradable, and conforms to industrial safety standards. Its mild odor and neutral pH make it suitable for regular use without compromising environmental or employee safety.